Aircraft engines are the power plants that propel aircraft through the sky. From the early days of aviation to the modern era, various engine types have been developed, each with unique characteristics and uses.

Piston Engines

Piston engines, reminiscent of the early days of flight, continue to power a vast array of light aircraft today. They function by converting the reciprocating motion of pistons into rotational motion, which in turn drives the aircraft’s propellers.

Radial Engines

Radial are a type of piston engine with cylinders arranged in a circle around the central crankshaft. This configuration was particularly popular in the early to mid-20th century, especially in military aircraft. The radial design allows for excellent air cooling, which is advantageous in combat situations where reliability and durability are paramount.

The distinctive appearance and sound are unmistakable, often associated with the classic warbirds of the past. Despite their older design, they are still in use today, particularly in vintage and historical aircraft, where their robustness is a valued feature.

Key Features

| Configuration | Cylinders arranged in a circle |

| Cooling | Air-cooled design |

| Power | High power output |

| Application | Historical and vintage aircraft |

Inline Engines

Inline engines present a streamlined alternative to the radial design, with all cylinders arranged in a single line. This layout is more aerodynamically efficient, making it a preferred choice for aircraft where speed and air resistance are significant considerations.

The incline’s design also allows for a more straightforward installation in the aircraft’s fuselage, contributing to a sleeker, more aerodynamic profile. However, this configuration can present challenges in terms of cooling, as the rear cylinders receive less airflow than those at the front.

Inline engines have powered some of the most iconic aircraft in history, including many World War II fighters. Today, they are less common but remain a critical part of aviation heritage, celebrated for their contribution to the development of high-performance aircraft.

Key Features

| Configuration | Straight line of cylinders |

| Aerodynamics | Low drag, high-speed capability |

| Cooling | Complex due to inline arrangement |

| Application | Historic performance aircraft |

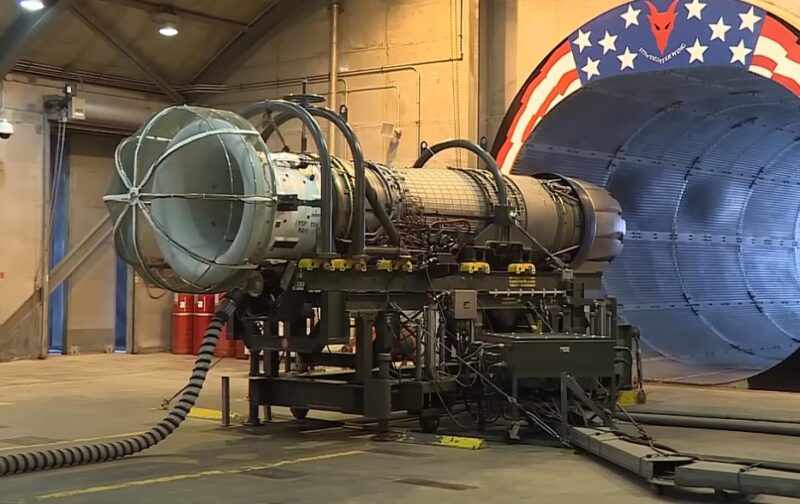

Turbine Engines

Turbine, encompassing turbojets, turbofans, turboprops, and turboshafts, have revolutionized air travel with their incredible power and efficiency. These models operate on the principle of jet propulsion, which involves drawing in air, compressing it, mixing it with fuel, igniting the mixture, and expelling it at high speeds to generate thrust.

Turbojet Engines

Turbojet engines are the purest form of jet engines, with a design that is straightforward yet powerful. They were the first engine type to enable sustained supersonic flight and have a simple operating principle: air is drawn into the engine, compressed by a series of compressor blades, mixed with fuel, and ignited.

The high-speed exhaust gases then pass through a turbine, which drives the compressor, and are expelled out the back, propelling the aircraft forward. This type is best suited for high-speed, high-altitude flight, and was widely used in early jet fighters and commercial jetliners.

However, turbojets are less fuel-efficient at lower speeds and altitudes compared to other turbine models, which has led to their decline in favor of more advanced designs.

Key Features

| Operation | Continuous combustion |

| Efficiency | High at supersonic speeds |

| Thrust | High-speed exhaust gases |

| Application | Early jet fighters, commercial jetliners |

Turbofan Engines

Turbofans are an evolution of the turbojet, designed to improve efficiency, especially at the speed ranges typical of commercial airliners. They feature a large fan at the front of the engine, which captures and accelerates a significant amount of air.

A portion of this air enters the core, where it is compressed, mixed with fuel, and ignited, while the rest is bypassed around the core, providing additional thrust.

The result is an engine that offers the high-speed capabilities of a turbojet with the added benefits of increased fuel efficiency and reduced noise. Turbofan engines are the most common type found on modern commercial aircraft, thanks to their balanced performance characteristics.

Key Features

| Operation | Bypass air mixed with core exhaust |

| Efficiency | Improved fuel efficiency at subsonic speeds |

| Noise | Reduced noise output |

| Application | Modern commercial airliners |

Turboprop Engines

Turboprop engines represent a hybrid approach, combining the reliability of propeller-driven propulsion with the power of a turbine engine. They are particularly efficient at lower flight speeds and are commonly used in regional airliners, cargo aircraft, and special mission planes.

Turboprops function by using a gas turbine to turn a propeller. Most of the energy is used to drive the propeller, with only a small portion contributing to exhaust thrust. This makes turboprops more fuel-efficient than turbojets at speeds below about 450 mph, which is why they are favored for short to medium-haul flights.

Key Features

| Operation | Gas turbine drives a propeller |

| Efficiency | High fuel efficiency at lower speeds |

| Speed Range | Optimal for below 450 mph |

| Application | Regional airliners, cargo aircraft |

Turboshaft Engines

Turboshaft engines are a variant of the turbine family, specifically designed to deliver power to a shaft that drives something other than a propeller. This type of engine is most commonly found in helicopters and some types of tanks. In helicopters, the turboshaft’s primary function is to drive the main rotor blades that provide lift and thrust.

Unlike turboprops, the exhaust gases in a turboshaft do not provide significant thrust; instead, nearly all the engine’s power is used to turn the rotor. This design allows for compact engine size and a high power-to-weight ratio, which is essential for vertical takeoff and landing (VTOL) aircraft.

Key Features

| Operation | Power delivery to a shaft |

| Power-to-Weight | High ratio, essential for VTOL |

| Thrust | Minimal exhaust thrust |

| Application | Helicopters, VTOL aircraft |

High-Speed Air Travel

Ramjet and scramjet engines represent the cutting edge of high-speed air travel, designed for speeds that turbojets and turbofans cannot efficiently reach. These models have no moving parts and rely on the aircraft’s high speed to ram air into the combustion chamber.

Ramjet Engines

Ramjet engines are simplest in terms of construction among the high-speed family. They operate efficiently at supersonic speeds between Mach 2 and Mach 6. A ramjet compresses the incoming air just by the speed of the aircraft and the shape of the intake, then fuel is added and ignited. The expansion of the exhaust gases propels the aircraft forward.

Ramjets are used in a variety of applications, most notably in missiles and experimental aircraft. They are not capable of operating at a standstill or low speeds, as they lack a mechanism to compress air at these velocities.

Key Features

| Operation | Air compression through aircraft speed |

| Speed Range | Efficient at Mach 2 to Mach 6 |

| Moving Parts | No moving parts |

| Application | Missiles, high-speed experimental aircraft |

Scramjet Engines

Scramjets are an evolution of ramjet technology, designed to operate at hypersonic speeds, typically above Mach 6. The term “scramjet” stands for Supersonic Combustion Ramjet, and the key difference from the ramjet is the speed of the airflow through the combustion chamber; it remains supersonic, allowing for much higher flight speeds.

Scramjets are at the forefront of hypersonic research and have the potential to revolutionize space access by significantly reducing the cost of launching payloads into orbit. They are, however, currently limited to experimental vehicles and are not yet used in commercial aviation.

Key Features

| Operation | Supersonic air combustion |

| Speed Range | Efficient at hypersonic speeds (Mach 6+) |

| Moving Parts | No moving parts, like ramjets |

| Application | Experimental vehicles, potential space access |

What is the Most Common Type Today?

The most common type in use today, particularly for commercial air travel, is the turbofan engine. This engine type is favored for its excellent balance of fuel efficiency, noise reduction, and performance over a wide range of speeds and altitudes.

The high bypass ratio turbofans are especially prevalent in commercial airliners because they can operate efficiently at the high subsonic speeds these aircraft typically fly at. They are also capable of providing the high thrust necessary for takeoff and climb, while still maintaining fuel efficiency during cruise, which is critical for long-haul flights.

Main Benefits

- Fuel Efficiency: High bypass ratios in modern turbofan engines contribute to lower fuel consumption, which is economically beneficial and reduces environmental impact.

- Reduced Noise: The bypassed air acts as a muffler, which significantly lowers the noise levels compared to older turbojet models, making turbofans more suitable for airports near residential areas.

- Versatility: Turbofans are capable of operating efficiently across a wide range of altitudes and airspeeds, making them suitable for various types of aircraft and flight profiles.

- High Thrust Output: They provide the necessary thrust for takeoff and climb, which is crucial for large, heavy aircraft.

- Lower Operating Costs: The efficiency and reliability of turbofan engines contribute to lower operating costs over the engine’s lifespan.

- Improved Safety: The reliability of turbofan has continually improved, leading to safer operations and fewer in-flight shutdowns or failures.

- Environmental Benefits: Modern turbofan produce fewer emissions than older engines, contributing to a reduced environmental footprint of aviation.

FAQs

Can piston engines be used for commercial airline travel?

While piston engines are reliable and have been used extensively in the past, they are generally not used for commercial airline travel today due to their lower efficiency at high altitudes and speeds compared to turbine engines. Commercial airlines prefer turbine engines, especially turbofans, for their better fuel efficiency, higher speed capabilities, and greater passenger capacity.

How do turboprop engines differ from turbofan engines in terms of flight range and speed?

Turboprop engines are most efficient at lower speeds and are typically used for shorter regional flights. They are ideal for speeds up to about 450 mph and can operate efficiently on routes that are too short for jet engines to reach optimal performance. Turbofan engines, on the other hand, are designed for higher speeds and longer ranges, making them the engine of choice for most commercial airliners on medium to long-haul flights.

Are ramjet engines used in any current commercial aircraft?

No, ramjet engines are not used in commercial aircraft. They are designed for supersonic speeds and do not function at the subsonic speeds at which commercial aircraft operate. Ramjets are primarily used in military applications, such as missiles and experimental high-speed aircraft.

Why aren’t scramjet engines more commonly used if they offer higher speeds?

Scramjet engines are capable of hypersonic speeds and are at the cutting edge of propulsion technology. However, they are currently not practical for commercial aviation due to their complexity, the current lack of infrastructure to support their operation, and the extreme conditions they operate under, which present numerous engineering challenges. They remain in the experimental stage and are primarily used in research and military applications.

Summary

The diversity of aircraft engines is a reflection of the varied demands of aviation. As technology advances, we can expect to see new developments that will continue to push the boundaries of speed, efficiency, and environmental sustainability in the skies. If you want to find out more about the aviation and many other topics, stay with us at Rpas Regulations.